DIERS Benchmarks

Case 7

Two-phase Homogeneous Download

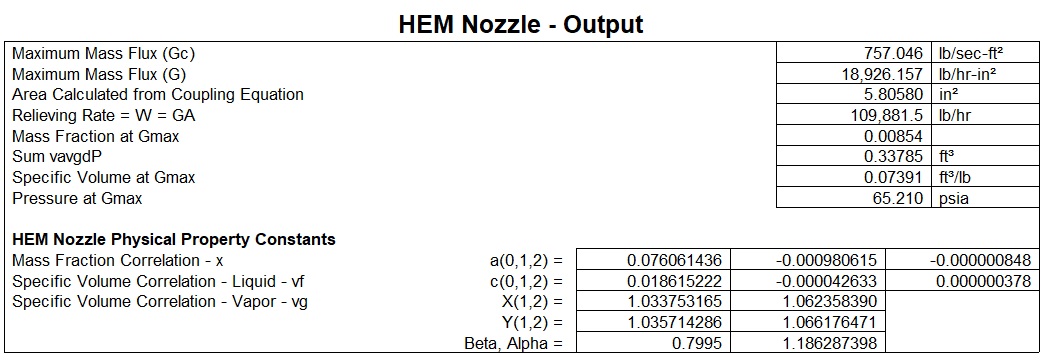

The homogeneous two-phase onset/disengagement is the classical DIERS model where the mass fraction entering the relief nozzle is based on the vessel volume fraction. Since the flow is homogeneous the mass fraction entering the relief nozzle is the same as the vessel mass fraction. The vessel is 85% full meaning that the vapor space or vapor volume fraction in the vessel is 15%. The Mach II will calculate the mass fraction by converting the vapor volume fraction in the vessel to a vessel mass fraction. This mass fraction is calculated to be 0.00051 and will be the initial mass fraction entering the relief nozzle. The fluid will flash as it enters the relief nozzle until it reaches the maximum fluid mass flux(Gmax), which is at the choke condition. This maximum mass fraction becomes the design basis of the relief device design or it is the basis for the rated capacity of the relief device when using an existing orifice size. The selected relief device is a 4 P 6, which is 6.38 in2 in area. The rated capacity is calculated by the equation, W = Gmax/A. where. "W", is the rated capacity of the relief device, "G(max)", is the maximum fluid flux, and "A", is the area of the relief device orifice.

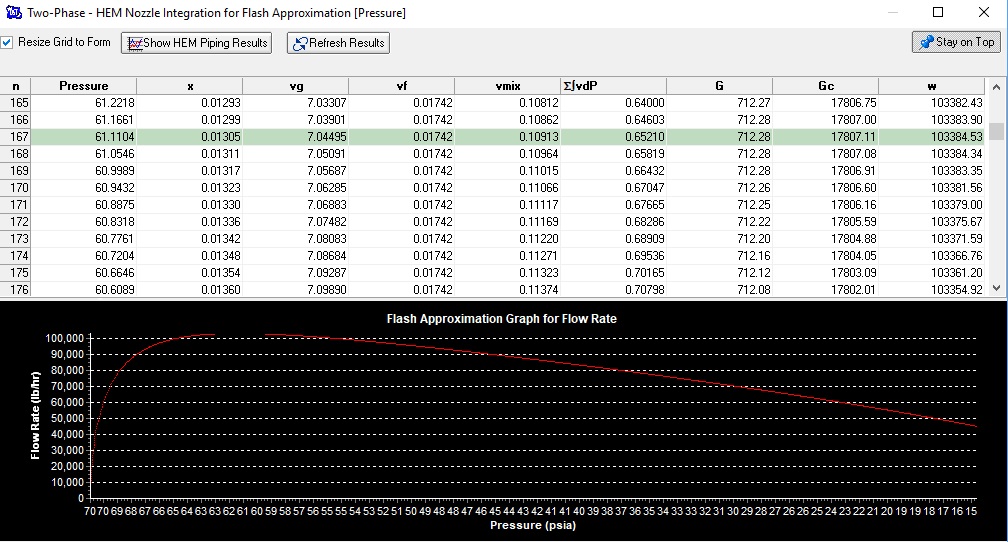

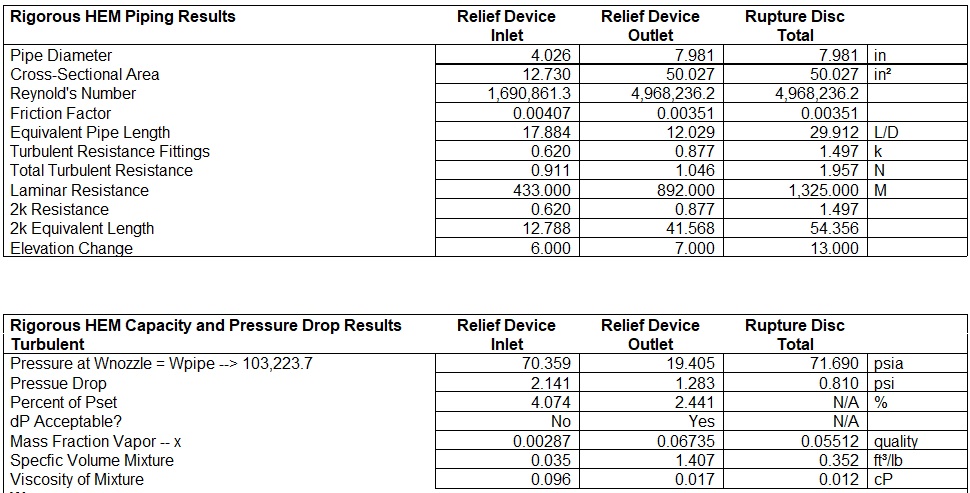

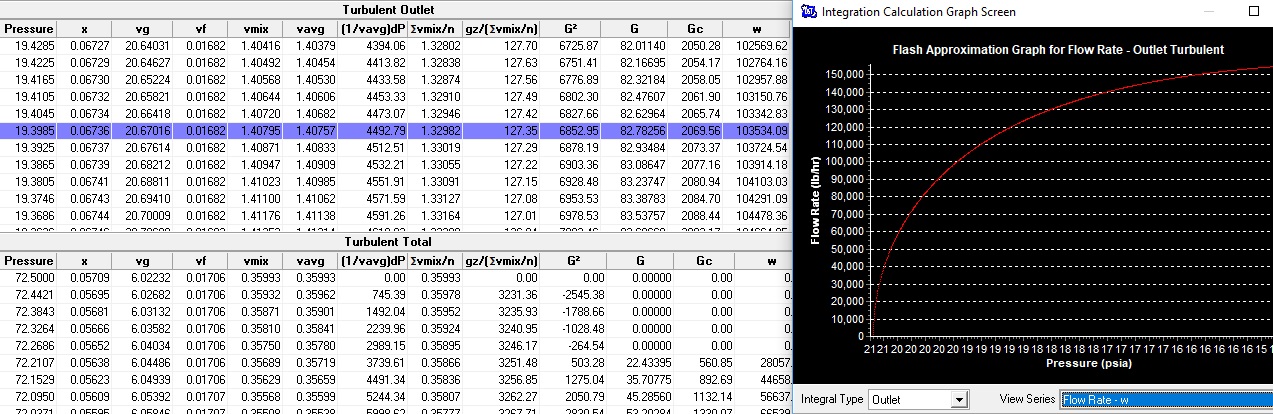

View the homogeneous direct integration(HDI) model for the nozzle below, to see the maximum fluid flux(Gmax) at the choke of 61.0 psia and maximum flowrate of 103, 223 lb/hr. Also view the homogeneous direct integration(HDI) model for the inlet and outlet piping to see the match flow and pressure where Wpipe = Wnozzle. The pipe can only see what the nozzle will flow. When the pipe flow reaches the nozzle flowrate the pressure drop is determined by the pressure difference between the relieving pressure and the inlet matching pressure shown on the blue line for the inlet pressure drop. And for the outlet pipe will be the difference between the initial outlet pressure and the matching blue line pressure where Wpipe = Wnozzle, on the outlet pipe direct integration table. The 6" outlet did not converge before reaching the back-pressure and so there is no blue line convergence. Instead the green line shows the maximum flow at 102,854 lb/hr. The outlet pipe needs to be increased to 8" for convergence as seen on the final pressie drop report and graph. This time the match where Wnozzle = Wpipe occurs at 19.4 psia. The difference between the converged pressure and the initial outlet pressie of 20.687, determines the pressure drop, which is equal to 20.687 -19.4 = 1.29 psi.

Mach II Nozzle Results & Piping Restyles Download

Flowrate (lbs/hr) Choke (psia) Quality (x) Inlet dP / %Pset Outlet dP /% Pset Pipe

Homogeneous Flow 109,882 65.2 0.009 ---------- ---------- nozzle

103,223 61.0 0.013 2.1 / 4.0 6.0 / 11.4 4 X 6

104,233 61.0 0.013 2.1 / 4.0 1.29 / 2.4 4 X 8

DIERS Results

RRERSP 105,729 66.7 0.007 ---------- ----------- nozzle

Grolmes 101,429 62.1 0.0121 1.9 / 3.5 8.2 / 15.5 4 X 6