Vapor Flow Case 1

The Mach II can perform the vapor only calculation using either the single-phase or two-phase engines. Each engine operates independently of the other. The single-phase engine uses the Darcy equation for performing the liquid pressure drop calculations and the adiabatic Shapiro relationships for vapor/gas calculations. The two-phase engine uses direct integration of the VdP integral to determine the maximum mass flux(Gmax) and the choke for the nozzle, inlet, and outlet piping. The results are similar. However when performing the vapor calculation using the two-phase engine you must select to enter "mass fraction data", and enter the mass fraction as 1.0 for inlet/nozzle property data, and for the outlet piping property data.

Summary Report (Two-phase Engine) Download

Vapor flow calculated 21.537 lb./hr. Nozzle

Flowrate (lb/hr) Choke Quality Inlet dP / %Pset Outlet dP / %Pset Piping

Vapor Flow 21,537 42.0 1.0 ------- ------- nozzle

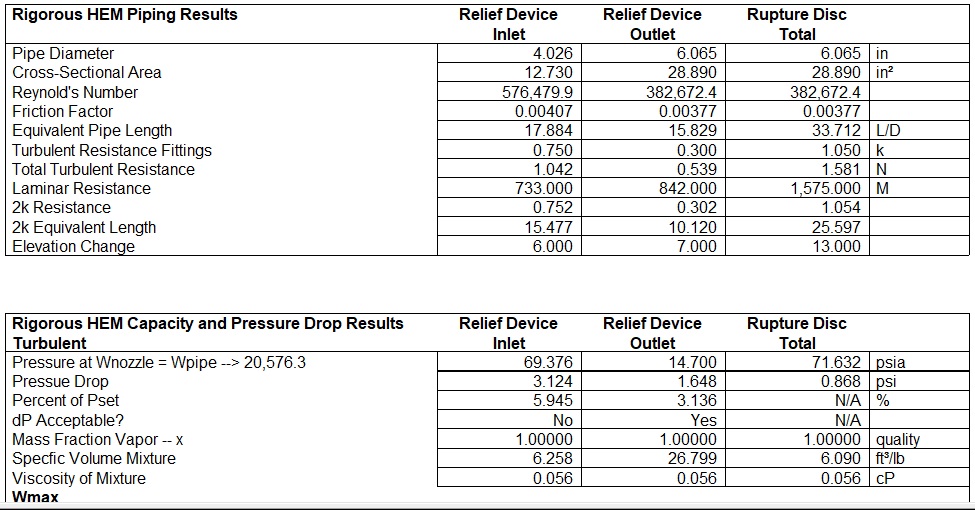

Vapor Flow 20,576 39.8 1.0 3.0 / 5.7 1.65 / 3.1 4 X 6

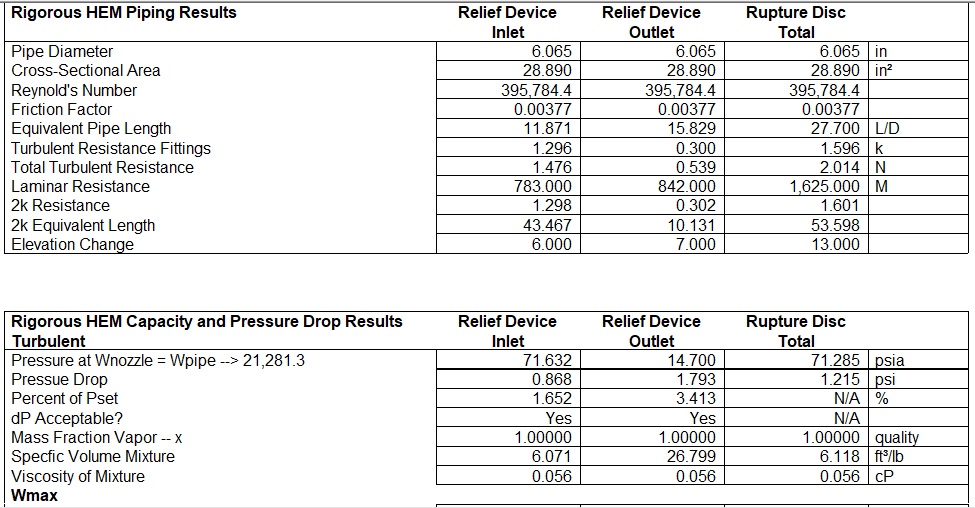

Vapor Flow 21,281 41.3 1.0 0.87 /1.7 1.8 / 3.4 6 X 6

Single-Phase Results reprinted for comparison

Flowrate (lbs/hr) Choke Quality Inlet dP /% Pset Outlet dP /% Pset Piping

Vapor Flow 21,667 --- 1.0 3.05 /5.80 2.15 /4.08 4 X 6

Vapor Flow 21,667 __ 1.0 0.84 /1.89 2.15 /4.08 6 X 6

Notice how the single-phase and two-phase engines give identical results. These results are also in line with the results from the DIERS benchmarks reported in the Fisher, Adair paper.

RRERSP (Fisher) 21, 010 39.4 1.0 3.1 / 5.9 1.8 / 3.4 4 X 6

RRERSP (Fisher) 22,818 39.4 1.0 ------ ------ nozzle