Guidelines for Pressure Relief Design

Piping/Pressure Drop Selection

The ASME code requires the pressure drop in the piping system be limited so that there is not a build-up of pressure in the piping system that would further increase the over-pressure in the system or reduce the capacity of the relief device. Flow resistance in the inlet and outlet piping causes this pressure drop. The flow resistance is caused by the straight pipe, the pipe fittings, such as elbows, tees, branches, and also due to elevation differences and velocity changes inside the pipe. All of this goes to make up the total resistance to flow inside the pipe. This total resistance can be express in two ways, either as a total equivalent length of straight pipe (L) or as a total resistance coefficient (K). The two are related by the equation K=f (L/D), where f is the friction factor in the pipe, L is the equivalent length, and D is the diameter of the pipe in feet. There are many correlations for determining the friction factor in the pipe and this is the most important part of the calculation. The program uses the Church Hill correlation for determination of the friction factor for both compressible and incompressible fluid flow.

For liquid pressure drop calculations the program uses the Darcy formula.

ΔP = ((f L/D) + sum K) v2/2g

Gas, Vpor and Steam Pressure Drop Calculations

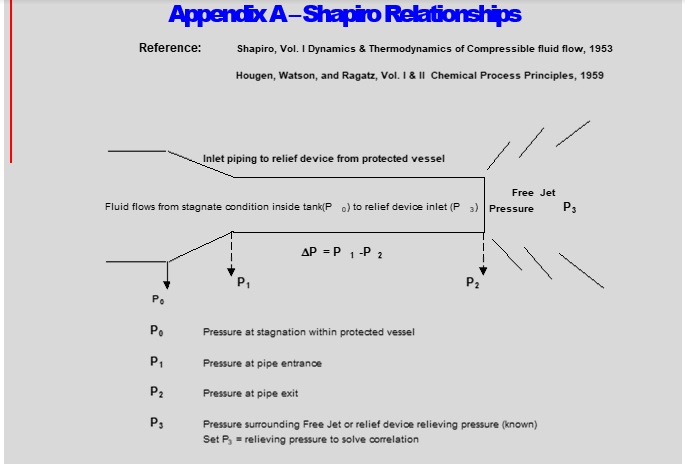

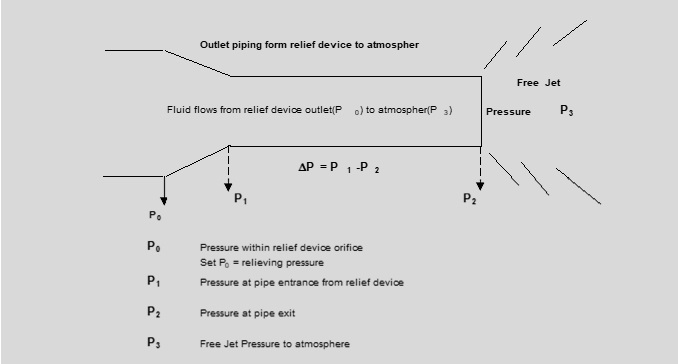

And for vapor, gas, and steam releases the program uses the Shapiro Relationship which is based on adiabatic flow. The Shapiro Relationship is the most interesting portion of the single-phase program subroutines and is used to determine the pressure drop for gases, vapors, and steam as well as the capacity required for the tube rupture scenario when vapor, gas, or steam is released.

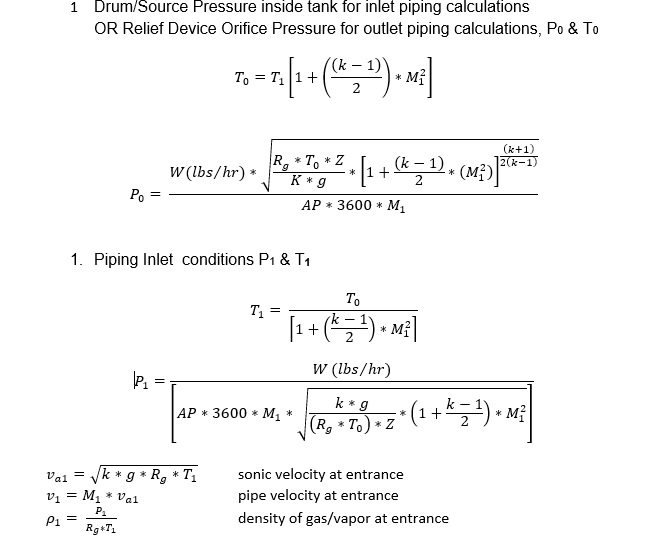

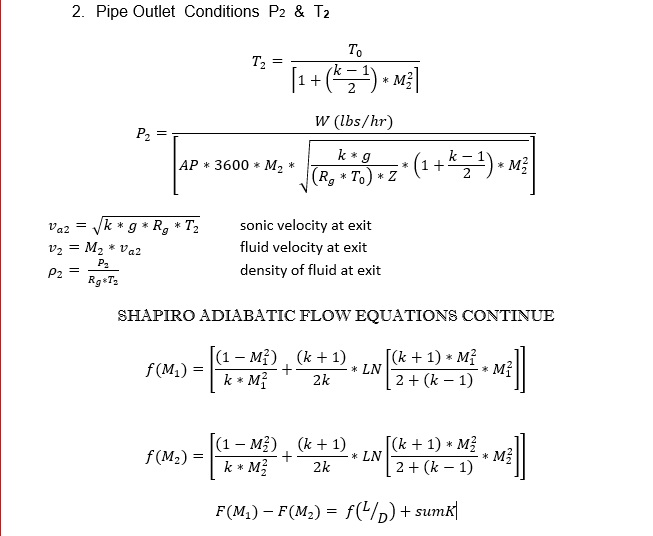

Shapiro Relationship Equations

Shapiro devised a set of formulas for determining the pressure drop/loss in a pipe based on the velocity difference at each end of the pipe relative to the speed of sound. Shapiro uses Mach numbers to describe the velocity of the fluid at each end of the pipe. He then uses a set of equations using these Mach numbers to calculate the energy at each end of the pipe. From there he relates the difference in energy between each end of the pipe to the total piping resistance inside the pipe. Therefore, by iterating these Mach numbers at each end of the pipe, until the difference in energy at each end of the pipe is equal to the total calculated piping resistance inside the pipe, the pressure drop is determined by convergence.