DIERS Benchmarks.

Case 11 High Viscosity Liquid Water (Two-phase Engine)

Case 11 high viscosity liquid water takes same data as case 10 for liquid water except that the viscosity of the lqiuid is constant at 1000 cP. For this case we will use the Mach Ii two-phase design engine and enter 1000 cP for each of the liquid viscosity data points from reliving pressure down to the exit pressure.

Mach II Nozzle Results & Piping Results Download

Two-phase high viscosity water

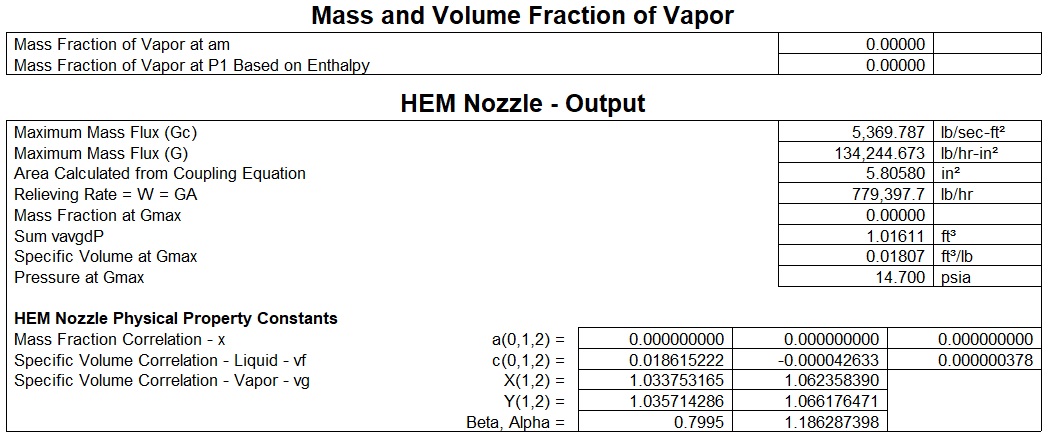

Flowrate (lbs/hr) Exit (psia) Quality (x) Inlet dP / %Pset Outlet dP /% Pset Piping 779, 398 14.7 0 ------ ------- nozzle

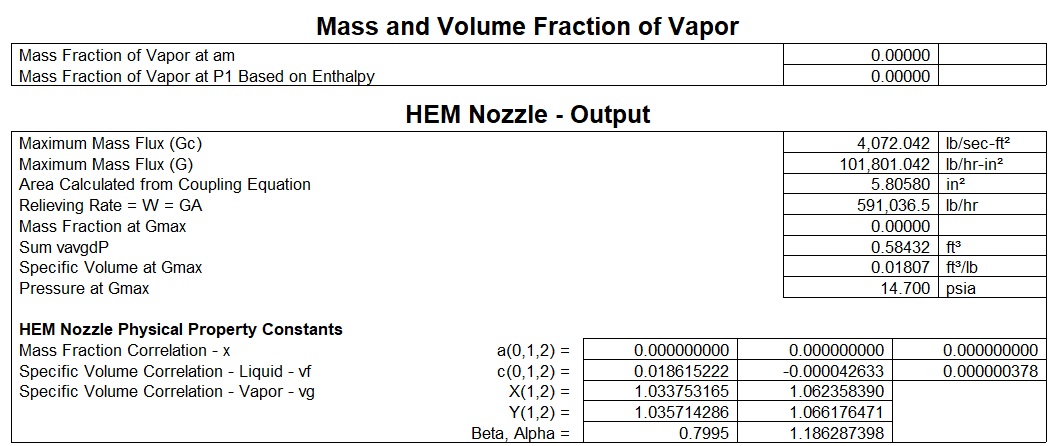

591,037 14.7 0 15.5 / 29.4 3.9 / 7.5 4 X 6

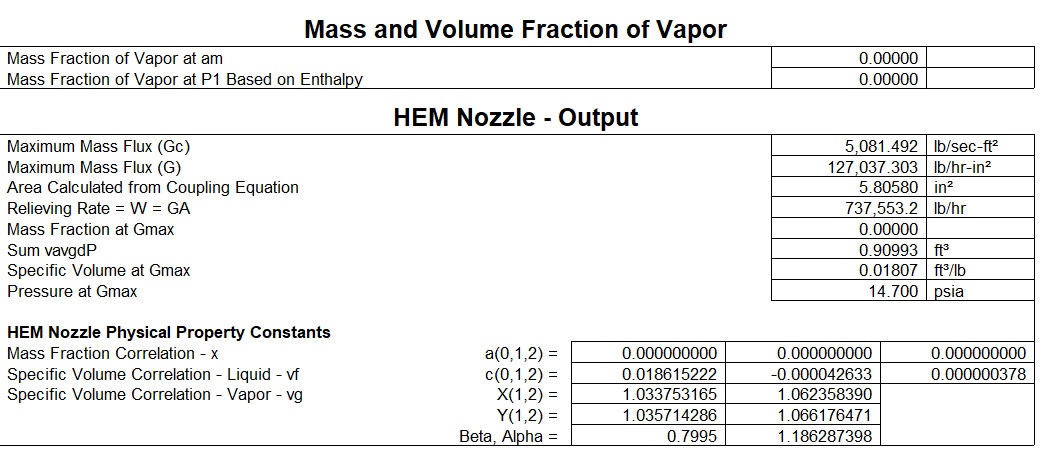

737,553 14.7 0 6.1 / 11.6 3.9 / 7.5 6 X 6

734,272 14.7 0 6.1 / 11.6 3.0 / 7.5 8 X 6

DIERS Results

Liquid Water Flowrate (lbs/hr) Exit (psia) Quality (x) Inlet dP / %Pset Outlet dP /% Pset Piping

RRERSP 778,100 14.7 0 ------- ------- nozzle

Shaw 577,363 14.7 0 14.9 / 28.4 7.9/ 15.0 4 X 6

RRERSP 668,014 14.7 0 4.7 / 9.2 7.0 / 13.8 6 X 6

RRERSP 689,678 14.7 0 1.8 / 3.5 7.1 / 14.1 8 X 6

The inlet and outlet pressure drop for the 4 X 6 agrees with the DIERS results. However, the 6 X 6, and 8 X 6, does not. The reason for this is that the Mach II uses crane to determine the reducer resistance for the inlet piping and it has been shown to be very conservative. See Hooper article on 2K and 3 K method for reducer resistance. Download